Dixon HF225

– Suitable for fusing 225-63mm diameter pipe.

– Robust, reliable and low maintenance.

– Self-contained hydraulic hand pump simplifies operation.

– Compact for trench work.

– Easy one-man operation.

– Joints rapidly prepared with the powerful electric Facer.

– Self-Centring Fittings Chuck – simple way to hold stub flanges.

– Heater provides controlled uniform surface temperature.

– Heater achieves working temperature in approximately 15 minutes.

– Replaceable non-stick cloth system for heater plate reduces production downtime.

– Reducing liners available for pipe and fittings.

Dixon HF350

– Suitable for fusing 355-110mm diameter pipe.

– Robust, reliable and low maintenance.

– Self-contained hydraulic hand pump simplifies operation.

– Unique pipe alignment mechanism overcomes pipe diameter mismatch.

– Wheels removable for trench work.

– Easy one-man operation.

– Joints rapidly prepared with the powerful multi speed Facer.

– Self-Centring Fittings Chuck – simple way to hold stub flanges.

– Heater provides controlled uniform surface temperature.

– Heater achieves working temperature in approximately 15 minutes.

– Replaceable non-stick cloth system for Heater plate reduces production downtime.

– Reducing Liners available for pipe and fittings.

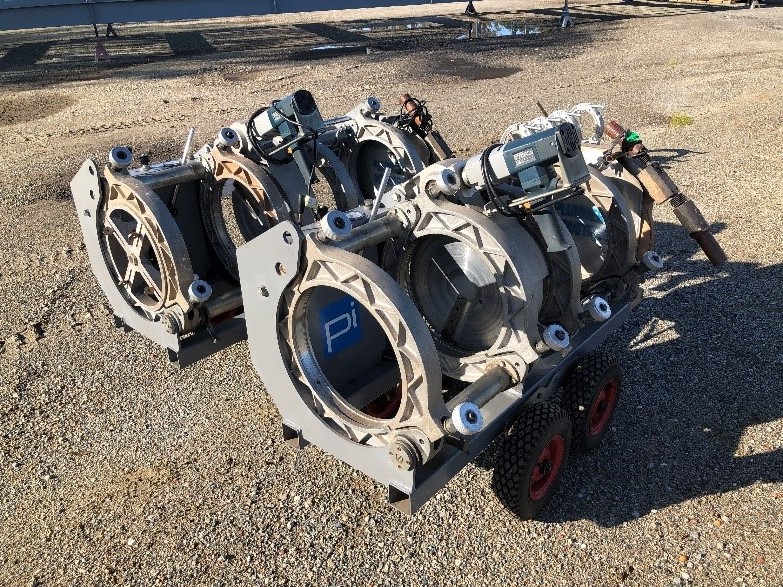

Dixon HF630

– Suitable for fusing 630-355mm diameter pipe.

– Robust and compact

– Heater, Facer and hydraulic power unit attached to the machine frame.

for minimal set up time and prevention of lifting injuries.

– Designed for low maintenance – tough and reliable for field or factory.

– Joints rapidly prepared with the powerful hydraulically driven Facer.

– The electric hydraulic controls enable pre-setting of pressures for each weld phase, ensuring consistent weld pressures and quality control.

– Unique pipe alignment mechanism overcomes pipe diameter mismatch.

– Heater provides controlled uniform surface temperature.

– Heater achieves working temperature in approximately 20 minutes.

– Replaceable non-stick cloth system for Heater plate reduces production downtime.

– Available with detachable wheel base.

– Reducing Liners available for pipe and fittings.

McElroy TracStar 500 Series 2

– Suitable for fusing 180-500mm diameter pipe.

– Hydraulic Pressure System: 2,300 PSI.

– Heater Power: 4,000-5,000 Watt.

– Fusion Pressure: 2,300 PSI.

– Centreline guidance system for equal distribution of force around the joint.

– ISO-compliant industrial Teflon-coated fusion plates.

– Dual hydraulic pipe lifts aid in loading and unloading pipe..

– 8+ hours operational fuel tank capacity for the Series II.

– Serrated jaws and inserts keep pipe from slipping during fusion.

– Hydraulic facer for facing the heaviest pipe walls with ease.

– Dual speed tracks.

McElroy TracStar 900

– Suitable for fusing 340-900mm diameter pipe.

– Hydraulic Pressure System: 2,300 PSI.

– Heater Power: 20,461 Watt.

– Fusion Pressure: 2,300 PSI.

– Centreline guidance system for equal distribution of force around the joint.

– ISO-compliant industrial Teflon-coated fusion plates.

– Dual hydraulic pipe lifts aid in loading and unloading pipe.

– Removable 3- or 4-jaw carriage for in-ditch use.

– Capable of top loading the heater and facer to maximise functionality within limited space.

– Features a wireless remote driving control.

– Dual speed tracks.

– Wireless remote control ensures safe, efficient working environment and precise machine placement.